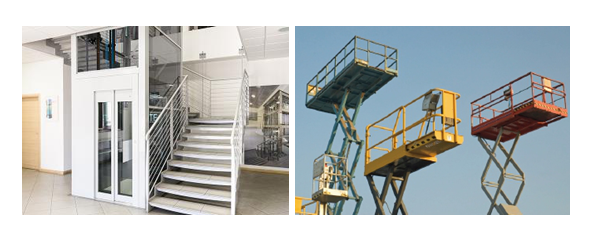

SMU Series Screw Pump is a reliable, low noise device that needs to be immersed in the tank and is suitable for applications requiring long service life and low cost, such as household elevators and elevators. It has the characteristics of small volume, low noise and stable operation, and occupies a high proportion of hydraulic elevator units in Europe and America.

SMU Series Screw Pump is a reliable, low noise device that needs to be immersed in the tank and is suitable for applications requiring long service life and low cost, such as household elevators and elevators. It has the characteristics of small volume, low noise and stable operation, and occupies a high proportion of hydraulic elevator units in Europe and America.

|

Common installation form |

Technical characteristics: |

technical data

|

Model |

GR20-25-32-40-45-55-60-70-80 |

|

Installation form |

Standard shaft or hollow shaft |

|

Oil port connection standard |

Bspp螺纹或sae Gas & nbsp; & nbsp; 3000 & nbsp; 焊接式法兰 |

|

Standard for connecting flange of pump body |

Conform to ISO 3019/2-IEC standard (and hollow shaft). |

|

Drive load |

No axial / radial load |

|

Rotation direction |

Turn clockwise from the direction of the pump shaft. |

|

Speed range |

300 - 3600rpm |

|

Flow range |

0 - 1200L/min |

|

Maximum working pressure |

80 bar |

|

Absolute pressure of suction port |

0.7 to 3bar (maximum pressure 10bar optional) |

|

Medium type |

Mineral oils HLP and HLVP Vegetable oil HETG-HEPG-HEE High viscosity lubricating oil |

|

Medium viscosity range |

4 to 2000cst |

|

Working medium temperature |

-20 to +100 C |

|

Ambient temperature range |

-20 to +60℃ |

|

Filtration accuracy |

Oil suction port 250? M pressure oil outlet 40-25? M optional |

|

Sealing material |

NBR、FPM、EPDM |

|

Material of pump body |

Alloy aluminum (cast iron, carbon steel optional) |

|

Rotor material |

Special hard alloy steel |

|

Cleanliness of oil |

Conform to NAS 1638 standard 10 level or ISO 4406 19/16 filtration ratio is greater than 75. |

|

Noise level |

Speed 2750rpm, 58-75dB (A), test standard IS0 4412 |

Application area:

SMU series three screw pumps are widely used in hydraulic power supply, lubrication and cooling applications, such as:

● Hydraulic elevator

● Lifting machinery

● Stereo garage

● Gear box

● Compressor

● Test equipment